Essentially meaning "continuous improvement", kaizen targets human resources and processes so as to anchor an industry for long-term and successful operation. Kaizen is a Japanese term coined in the period after World War II when businesses were trying to cope with the effects of the war. "Kai" translates to the word "change", and "zen" means "good". Kaizen produced significant results for companies like Toyota and has become a popular production philosophy all over the world.

In Lean manufacturing, Kaizen is the practice of continually making small, incremental improvements for a safer, more productive, and efficient workplace. This foundational Lean manufacturing method stitches continuous improvement into the fabric of your company's culture, which means managers, team leaders, and workers alike will be constantly searching for ways to improve processes and tighten standards. Kaizen reviews and training teaches new employees how to apply Kaizen principles to their work, which means Kaizen stays sustainable for years to come.

The Process of Continuous Improvement in the Workplace

Continuous improvement is the process of constantly making things better than they were before. Kaizen can be defined as the philosophy and practice of continuous improvement. It refers to the practice of looking for ways to improve work processes on a regular basis. The practice involves small, incremental changes rather that large changes. With Kaizen, all people within the organization look for possible improvement opportunities, not just managers or executives.

Without Kaizen

- No structure to the improvement process; few set procedures

- Goals are not defined or are vague/difficult to measure

- Changes are made to processes infrequently; little reflection on their effectiveness

- No plan exists for improvement; improvement is haphazard

With Kaizen

- Consistent, ongoing process of improvement takes place

- Improvement process has clearly defined, measurable goals

- Constant review of successes occurs, and the improvement process itself is evaluated

- Consistency of the process leads to new, higher goals

Kaizen Philosophy

East vs. West

Masaaki Imai believed that the East and West used the concept of Continuous Improvement differently. Imai believed that the Japanese (in the east) used a gradualist method. This is what Imai called Kaizen. Imai believed the Western businesses used the great-leap-forward methodology. Imai referred to this as Innovation. The Eastern model of small, incremental change looks at the big picture. These changes may seem insignificant when they're implemented, but over time they can add up to significant improvements. In this model, the focus is on the long-term. Imai believed that the eastern model of improvement took small steps for long-term, continuous incremental gradual change. The east used everyone in the company, and everyone collectively worked to maintain and improve. Imai saw this approach as having little investment but needed a lot of effort to maintain. He saw it as better for slow economic growth.

The Western model of improvement prefers to see results fast. Consequently, large changes whose results can be seen quickly tend to be implemented. The upside of this method is positive gains are observed right away, which tends to please company leaders and can motivate employees. The downside is backsliding; organizations that always implement sudden, big changes often see those improvements fade over time.

Imai believed that the western model of improvement took big steps for short-term, intermittent abrupt change. The west used a select few people in the company and those individuals worked to scrap and rebuild. Imai saw this approach as having a large investment but small effort to maintain. He saw it as better for fast economic growth.

Kaizen tends to fall into the Eastern model for improvement; smaller changes are made on a regular basis and over time they may provide a business with many benefits. People can perform tasks more easily, feel empowered that they can make changes themselves, and find real ways to help the business. One of the reasons small changes can be beneficial is they tend to be low cost and fairly easy to implement. If for some reason a change doesn't work out, not much harm has been done because few resources went into the change in the first place.

Benefits

Kaizen benefits organizations for many reasons. Some of these benefits are:

- Smoother, more effective processes

- Cleaner, safer workspaces

- Higher quality products and/or services

- Lower costs

- Improved employee morale and engagement

- Better customer service

Respect for People

In kaizen, all workers must feel respected so that they are comfortable making suggestions for process improvements. This means management must believe workers are capable of making changes. People know their own jobs better than anyone else does, so they often have insights about possible improvements that people not doing the job on a daily basis won't have. It's important to note that when people are asked to look for possible improvements as part of kaizen, they shouldn't just be asked to look for cost savings. Some improvements may not result in direct cost savings, but they could make a process run smoother or make the work environment better for the people in it.

People should look for improvements that will make their work function better, and in turn, these improvements may help the company and its customers. People should also be encouraged to test out ideas themselves and make changes as needed. Employees might choose to consult a co-worker or supervisor first, or if the idea is small enough, an employee might go ahead and implement the idea to see how it goes (depending on the policies of the workplace - some facilities prefer that employees always consult a supervisor before trying out an idea). In general, workplaces that use kaizen trust people to try things out and don't always rely on management to make every decision.

Role of Management

Management plays a critical role in kaizen's success and should:

- Looking for ways to improve their own work

- Help maintain and improve standards

- Provide goals or targets for improvement

- Support actions with evidence

Every workplace is unique and the strategies that help one facility improve may not work in another. Management's job is to support people while strategies are tested out and provide general guidance about where the organization is going. When standards change, management should make sure everyone is aware of the changes and verify that the changes are documented. Whenever management decides to implement a change, showing data to support it helps facilitate buy-in from others in the organization because people don't feel like management makes decisions on a whim. Employees can see that changes are made purposefully in order to further the goals of the organization.

Tools of Kaizen

Kaizen aims to raise efficiency and productivity, but it does so by promoting a healthy working environment for employees. This, in turn, creates an organized and creative work environment that enriches the company, employees, and the services rendered to the consumer. Kaizen works in a cycle that it requires cooperation in all departments, and may even extend to suppliers.

PDCA Cycle

A prominent example of Kaizen is the implementation of a process called PDCA cycle. This is the Plan, Do, Check, Act method. The first step in PDCA is execution of the plan and accumulation of data, which will be used later for comparisons. When results are achieved, they are then checked and compared to the expected output. The results are then discussed and refined, to come up with a new plan. The application of the new plan is the last step of the cycle, then it begins again with tests and data accumulation. If the process is recurring and the data is measurable, then every cycle leads to improvement.

PDCA is a repetitive method and guarantees that knowledge of the production process will increase, and thus result in improvements. This is a perfect example of Kaizen, as improvements are cyclic and continuous.

Quality Circles

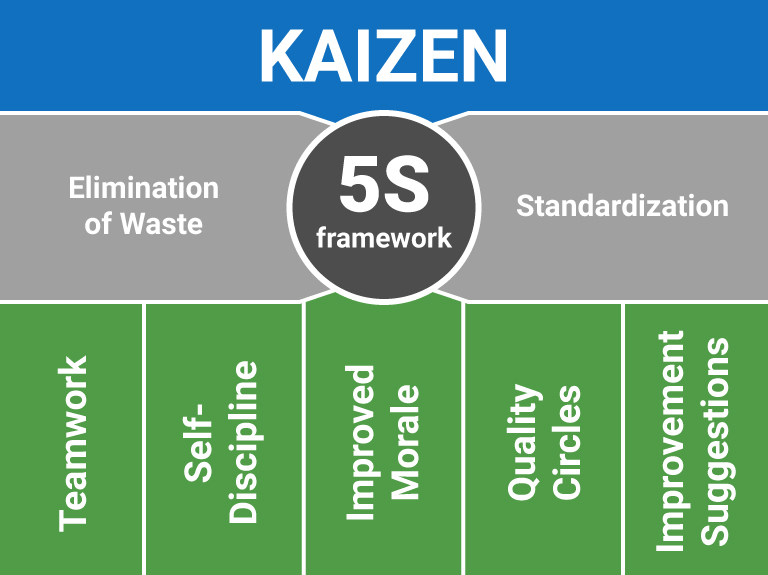

These elements are teamwork, self-discipline, improved morale, quality circles and suggestions. While most of these terms are fairly straight-forward, "quality circles" is a term new to a lot of people. Quality Circles and Suggestions are two of the main forces behind the success that Toyota has had with Kaizen.

Circles are teams that focus on identifying, analyzing and proposing solutions to work problems. It is composed of students and/or workers with a team leader and encourages development and expression of individual ideas rather than delegating individual jobs. This helps to focus on resolving problems, rather than pointing fingers when a mistake is made. Japanese businesses usually consider a production line as an already established quality circle in that the quick identification of a problem in the first phase of production can reduce major problems down the line. Each worker is provided training on troubleshooting abnormalities that arise in their work station. If each station executes quality control, reduction of expenses and time creates an impact.

5S

Kaizen is built on a 5S framework with elimination of waste and standardization at the forefront. 5S lays down a strong foundation for future Kaizen activities. 5S establishes an organization system in which everyone in the workplace participates to remove clutter and set spaces efficiently. While a space is cleaned and organized with 5S, managers should encourage operators and frontline workers to make improvement suggestions. This kind of system makes it much easier for people to spot improvement opportunities hiding in plain sight while promoting teamwork and self-discipline.

Kaizen Events

Although many companies choose to practice the Kaizen philosophy in their every day activities, Kaizen events can come in handy for bigger projects. A Kaizen event (also known as a Kaizen blitz) is a scheduled improvement process that takes place over the course of a few hours, days, or may even stretch into a couple weeks. An event team is established and assigned a focus.

Kaizen events are used for a number of ways including process changes, layout changes in the facility, waste elimination, and standardization. Definitively establishing the scope of a Kaizen event is key to the success of the blitz. Improvement projects often start with a reasonable scope, but overtime become too large and unmanageable. During the planning phase, the Kaizen team will need to choose an area or process for improvement and identify the scope of the event.

Kaizen & Continuous Improvement

The Kaizen mindset of continuous improvement makes for a more productive and efficient workplace by implementing small changes and emphasizing the involvement of all employees. Kaizen establishes a consistent process for improvement, defines the organization’s goals, and gives managers the tools they need to reach those goals.