TAKE CONTROL OF YOUR FACILITY WITH A 5S SYSTEM.

Like all Lean manufacturing concepts, 5S approaches seek to improve efficiency and production. 5S focuses on creating a system of organization that is both easy to maintain and improves productivity and safety. 5S Today is dedicated to setting your company up for success with 5S.

Featured Products

What is 5S?

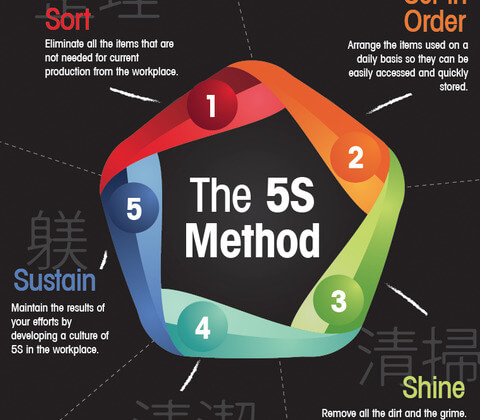

The 5S System is a foundational part of Lean manufacturing, a methodology for eliminating waste and increasing value in work processes.

The 5S System is a foundational part of Lean manufacturing, a methodology for eliminating waste and increasing value in work processes.

5S stands for Sort, Set in Order, Shine, Standardize, and Sustain. These steps establish procedures for organizing and maintaining the workplace and help continually improve production so you can increase efficiency.

Not sure which floor tape you need?

Use the floor tape finder to help you make the right choice for your application.

5S in Action